Robert Manning used to be a manufacturer in Sunset Park, and he’d like to be one again. As neighborhood groups fight to preserve and renew Brooklyn’s working waterfront amid a possible rezoning of Industry City, the New York City native hopes to make a case for his own longstanding proposal to create a textile manufacturing hub with the help of City Hall – and now, perhaps, local councilman Carlos Menchaca in particular.

An artist, Manning worked in the music and film industries before a friend, David Kushner, introduced him to textiles. Kushner (no relation to President Trump’s son-in-law) belonged to a family whose involvement in the textile industry stretched back to the late 1800s, and he perceived new cause for excitement in the technological developments of the 1990s.

Starting in the 1960s, New York City’s planned deindustrialization had shipped much of its textile work to foreign countries, but the novel industry of digital textile printing appeared to offer a fresh chance for New York to compete in the global economy: relying on cutting-edge machines that had not yet become available in every part of the world, the digital method required less space and less human labor than traditional textile manufacturing. It also used up less material and produced less waste.

Manning joined Kushner’s company, where they produced fabrics that – to the amazement even of themselves – faithfully replicated designers’ far-flung color schemes and intricate patterns. Their work initially drew the interest of corporate giants like Hewlett-Packard and Kimberly-Clark, but financial backers began to withdraw when they realized that digital textile manufacturing still had a long way to go. “At that time, we were literally printing three yards an hour, and that’s just impossibly slow if you’re trying to actually make a business out of it,” Manning acknowledged.

Kushner and Manning invested in research and development and paid for a number of patents. At the same time, they struggled to keep pace with rising rents, which caused them to lose their space on 24th Street in Manhattan. They moved to Industry City, but after Jamestown Properties and other real estate investors bought the complex in 2013, another rent hike sent them packing. They tried a couple more locations, but Kushner’s health started to decline, and the business eventually fell apart.

Digital textile printers have improved since their early years and now yield 40 to 50 yards of fabric per hour. Manning would like to get back into the game and has formulated what he regards as a sound business plan for his reentry. But even if all the numbers add up, few investors in New York want to get into textiles. By now, the digital side of the industry, like the analogue, has moved overseas, and perhaps as a result, technological progress – especially in terms of the digital color spectrum – has begun to stall or even retreat.

“The Chinese government was subsidizing their digital printing industry, and we were being starved to death,” Manning described. “They were basically doing what they always do, which is copy everyone’s technology, so they weren’t about to be innovating.”

A prosocial endeavor

According to Manning, New York City could, with the backing of Mayor de Blasio, reclaim the vanguard of the textile industry – and to do so would bolster the city’s longtime position as a worldwide leader in fashion and the arts, since textile manufacturers can play an integral, symbiotic role in these industries as well. Throw pillows and runway gowns both begin as ideas; textile printers turn them into real life.

“You can upload an image and get it printed in China, but it’s not the same thing as having people coming by – there’s a real value to having something local, and a lot of the fashion designers would agree with that,” Manning asserted. “You want to be able to see the tests and samples that you’ve printed and do the back-and-forth and finally arrive on the colors and patterns and the fabrics.”

Manning, who lives in Sunset Park, has long hoped to see the city partner with a developer to build subsidized space for the local textile industry. He believes that his own operation could sustain itself without public handouts – that is, given the chance, it would offer sufficient returns to make private capital happy – but a discounted rent would lower his costs and make his business plan more attractive to investors who haven’t considered the profit potential of domestic textiles in a long time. It would also allow him to adopt a less strictly revenue-focused approach and to think more about expanding the artistic possibilities of digital textile printing.

In his view, the city should fund a textile incubator that would co-locate sewers, weavers, and embroiderers with printers, designers, and research-and-development firms. Manning envisions a creative ecosystem that would amount to more than the sum of its parts and would serve as a resource not only for local fashion houses and merchants but also for artists, photographers, interior decorators, students at FIT and Pratt, and younger schoolchildren who could witness advanced manufacturing in their own backyard.

“There’s all this creative energy that needs to be tapped into,” Manning enthused. “It’s educational – there’s so much to learn right there where the printhead meets the fabric.” In his view, the color management software designed by Manning’s former team for digital printing remains highly useful and novel, and he’d love to see what local kids could do with it as schools in the area embrace STEAM programming.

In 2017, de Blasio announced that the New York City Economic Development Corporation (EDC) would spend $136 million to redevelop a section of Bush Terminal in Sunset Park. Branded the “Made in NY” campus, it will function as a hub for TV and film production as well as garment manufacturing. Manning is watching the development with interest, but no one at the EDC has yet said anything about textile production on the site.

Paging Andrew Kimball

In September, Sunset Park’s councilman, Carlos Menchaca, weighed in on the proposed rezoning of the adjacent Industry City. He rejected Jamestown’s plan to build hotels on the site, but he said he’d allow a bonus on retail space if, among other conditions, Industry City agreed to allot an unspecified square footage to a nonprofit that would offer subleases to small manufacturers at affordable rates.

The fate of Industry City’s rezoning remains up in the air, but Manning believes that his textile incubator would be a perfect fit for Menchaca’s imagined arrangement. He met with the councilman in November to discuss the matter. His own digital textile printing business wouldn’t offer as many jobs as old-school textile manufacturing did, but some hiring would take place, and the modern process doesn’t have nearly as many environmental drawbacks.

That’s especially true of Manning’s own methods, which make use of “historical dyes” that “go back hundreds of years. They’re water-soluble. They’re not like what most of the digital printing in the US is, which is pigment inks, dye sublimation – that stuff’s much more toxic.”

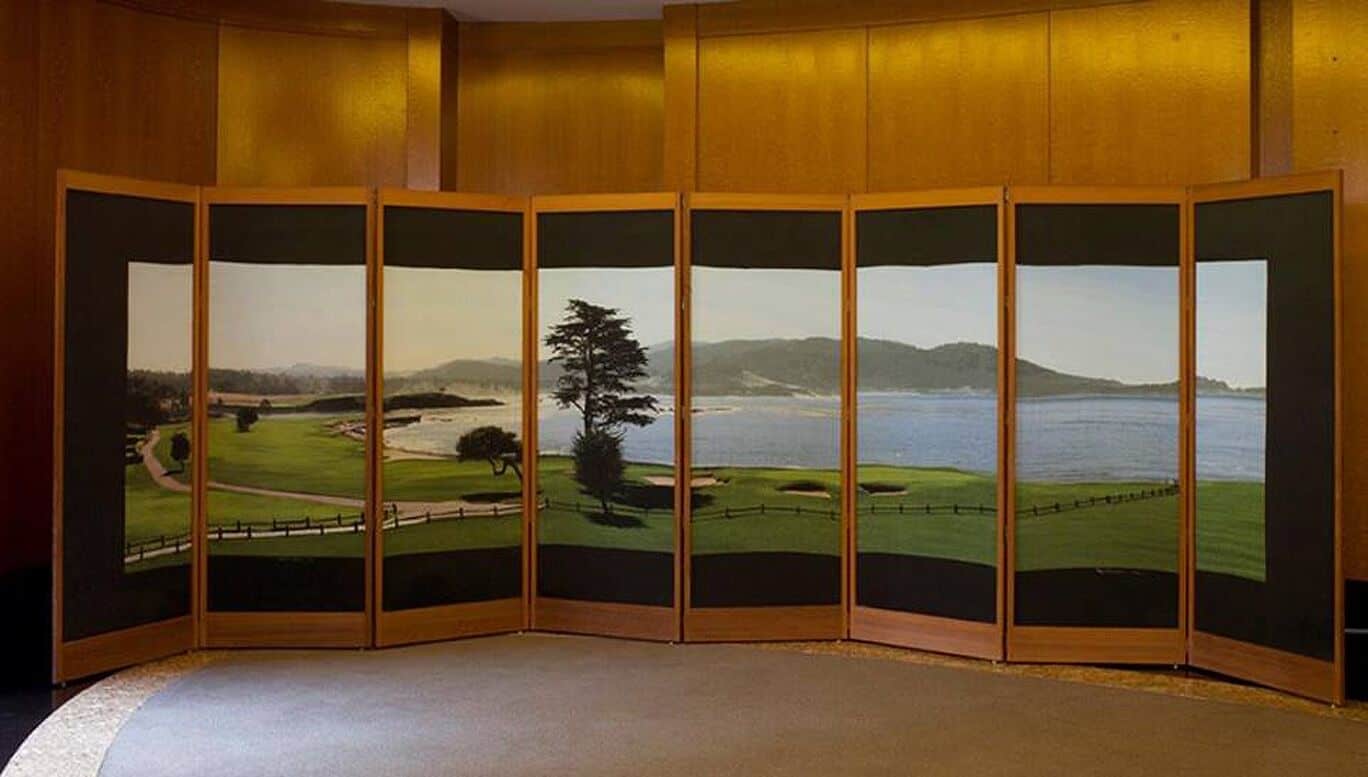

In the past, Manning has printed everything from art museum installations to promotional banners. For the 2008 presidential inauguration, the Obama team commissioned him to print a commemorative scarf. “The thing that’s exciting and intriguing about this is that it’s not tied into the apparel industry. People always kind of think in those terms – they’re fixated on saving the Garment District. And my focus has been on the broader umbrella of textiles. Apparel fits into that, but there are a lot of other categories,” he explained.

In late October, Industry City officially submitted its rezoning application for certification by the Department of City Planning, triggering the seven-month Uniform Land Use Review Procedure (ULURP). Unless Menchaca can secure a stakeholder-approved community benefits agreement before the end of the public process, he will, by his own account, vote no on the proposal. Until then, manufacturing advocates will continue their efforts to turn a possibility feared by much of blue-collar Sunset Park to their advantage. Manning’s plan is sure to be one of several that will vie for the city’s and neighborhood’s attention.

One Comment

Pingback: A possible New York textile industry for the future – The Red Hook Star-Revue | Aleemah Art News UK